EMI / RFI Shielding

Vivid strives to provide the most effective EMI shielding techniques on the market to increase efficiency for our customer’s products. EMI Shielding is a technique used to improve the electromagnetic compatibility of an electronic device. Undesired waves generated by all electronic devices can cause a product to malfunction. Vivid’s goal is to minimize or completely avoid the excess electrical noise caused by electromagnetic interference or radio frequency interference through EMI shielding.

| Shielding Material | Specific Gravity | Wet Density | Resistivity ohms per sq 0.001" | Continuous Temperature | Shelf Life, Months | Drying Time, Hours | Shielding, db @ 10MHz | Shielding, db @ 100MHz | Shielding db @ 1 GHz |

|---|---|---|---|---|---|---|---|---|---|

| CONDUCTIVE PAINTS | |||||||||

| Pure Silver acrylic 1-part system | 3.9 | 1.9 | 0.004 | -65 to 200 | 12 | 1 | 67 | 93 | 97 |

| Pure Silver Epoxy, 2-part system | 2.8 | 1.0 | 0.1 | -25 to 180 | 24 | 3 | 59 | 81 | 87 |

| Pure Silver Solvent | 3.6 | 1.5 | 0.05 | -65 to 200 | 12 | 1/2 | 57 | 82 | 89 |

| Nickel | 3.95 | 1.9 | 3.0 | -60 to 180 | 6 | 24 | 35 | 47 | 57 |

| Carbon | 0.8 | 0.4 | 10 | -65 to 255 | 12 | 24 | 27 | 35 | 41 |

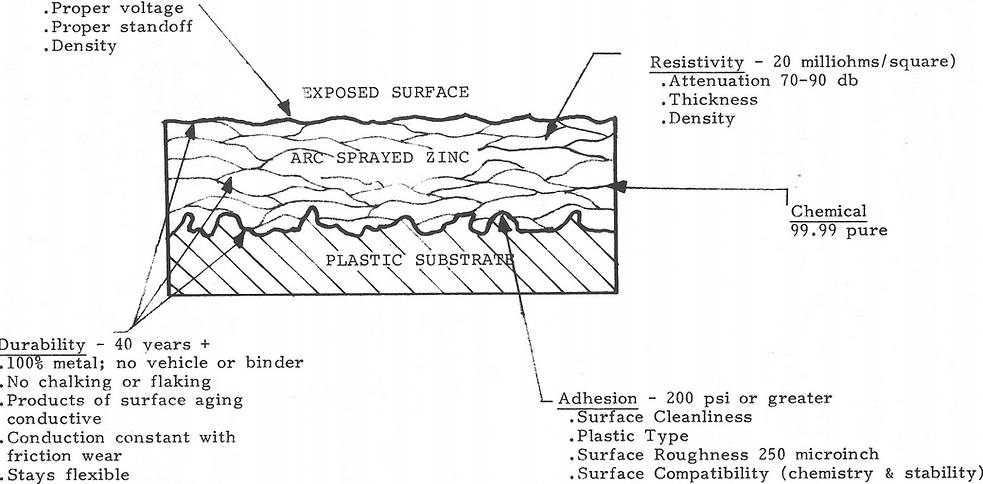

| Thermal Spray | |||||||||

| Arc Sprayed Zinc | 7 | 7 | 0.002 | -65 to 675 | infinite | 0 | 106 | 92 | 98 |

We provide many options for EMI shielding. Some final products have to survive through more extreme environments. Whether it is EMI shielding through a thermal sprayed metal, traditional paint, or some sort of hybrid, Vivid will have a competitive price and an impressive lead time.

EMI shielding is important because of our reliance on advanced technology for an array of purposes. Telecommunications rely on EMI shielding to protect reception from radio emissions that are approximately the same frequency. Hospitals use EMI shielding and comply with FDA regulations to protect electric wheelchairs, pacemakers, and anesthesia machines. The aircraft industry EMI shields flight control and sensitive navigation systems from radar beams. EMI Shielding is extremely important to protect a products efficiency because the slightest malfunction of an electronic product could have damaging consequences.

EMI shielding effectiveness depends on the frequency of the interfering presence. The coatings that make up the enclosures are typically silver, silver coated copper, or nickel. Silver gives the highest quality protection but is more expensive. Nickel gives a fair amount of protection and is the least expensive option. Silver coated copper provides a decent EMI shielding protection protection and is slightly cheaper than silver. Capacitively-coupled noise may be reduced by increasing conductor separation, but it is most easily cured by using a Faraday shield between the signal source and the affected node. The Faraday shield works by routing the displacement current directly into the ground.

EMI Shielding Materials

- Nickel

- Silver

- Copper

- Zinc