Painting Plastic and Metals

Vivid provides services within all sorts of solvent based paints for painting plastic. Our staff is experienced in painting plastic and metals substrates of all shapes, sizes and chemical make-ups. We provide all preparatory services as well including cleaning and masking, a key ingredient to successfully painting plastic. Varying paints provide different functional and aesthetic services.

Painting plastic metal over the last 27 years, Vivid has experience in all sorts of paints. These paints have different ranges of durability, dirt resistance, and environmental friendliness. We have the knowledge to match paints with almost any substrate.

Class A Painting Plastic for medical devices, telecom, data center enclosures, and automotive has become a large part of our business and we know what it takes to meet the narrowest quality standards. Painting Plastic becomes an important part of the marketing of some of the largest and exciting companies in the Silicon Valley.

Polyurethane

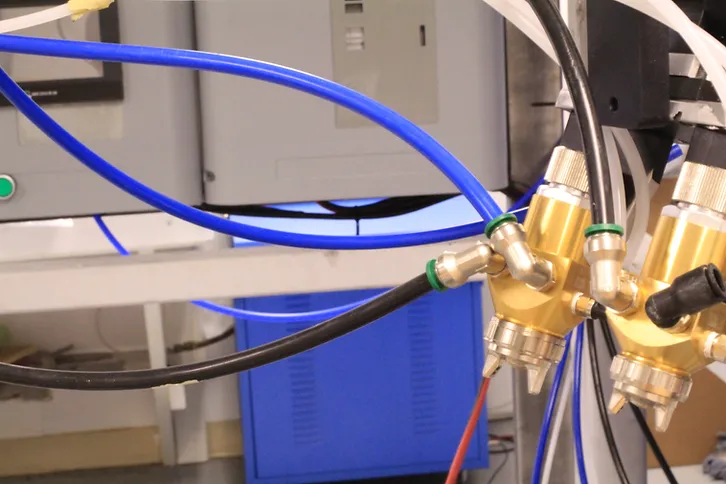

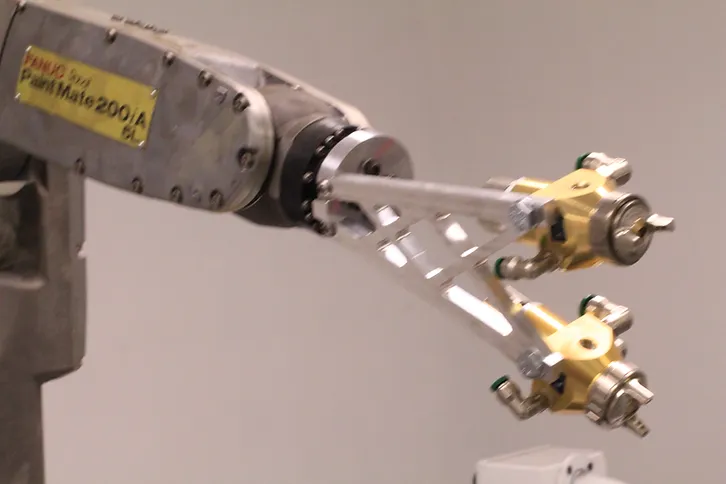

Polyurethane is a polymer composed of a chain of organic units. The polyurethane painting plastic or metal process begins with thorough substrate preparation which Vivid provides through our media blast technologies or orbital sanding. The coating is then applied through using a plural component pump and gun. The material is pumped to the tip of the gun at a high pressure and temperature. The tip of the gun is where it is atomized and sprayed for painting plastic.

Polyurethane advantages:

- Resistant to corrosion and abrasion

- Exceptional weathering performance characteristics

- High gloss finish

- Thin film finish

- Has excellent chemical resistance

Waterbase

Waterbase coatings for painting plastic and metals have a primary ingredient of one or more solvents. Solvents aid in dissolving the paint materials to form a sprayable liquid mixture. Once painting plastic or metal is complete, the curing process may be required. The baking process depends on the type of water coating involved as some need to be heated to form a strong molecular bond and others just need the water to evaporate. When painting plastic, the curing process is typically not needed. The high curing process needs temperatures near 400 degrees Fahrenheit for approximately ten minutes. The low curing paints needs far less heat, and could also be completed through a dehumidification process. The evaporation rate is dependent upon the vapor pressure difference between the coating’s water and the air being circulated over the surface part.

Waterbase advantages:

- Cost-effective coating option

- Reduce volatile organic compounds (VOC) that may interfere with environmental restrictions

- Abrasion resistant

- Ability to be recoated

Powder

The powder coating process begins with preparation. The coating can’t be applied properly without an exceptionally clean surface. The material being coated must be free from oil, grease, metal oxides, even the natural oils from our fingertips. At Vivid we recognize how essential this initial step is and have some of the most modern equipment and experienced personnel to carefully perform media blasting.

Applying the coating is done with an electrostatic gun which imparts a positive electric charge on the powder and is then sprayed using compressed air towards the grounded material.

Curing is a process in which the thermoset powder is exposed to a certain amount of time in an elevated temperature at which time it melts and chemically reacts to form a polymer of increased molecular weight in a network like structure. Cure schedules can differ based on the customers specification.

Powder coating is a free flowing dry powder that is applied to a material through positive electrostatic force and later cured at a high temperature to form a molecular bond.

Powder Coating advantages:

- Provides a thicker coating without the chance of paint running

- Has little to no appearance difference between horizontal and vertical paint strokes

- Has no volatile organic compounds (VOC) to meet with environmental standards

- Abrasion resistant and extremely tough

- Dialectic nature of coating provides extra protection against corrosion