Rough Coatings Providing Rough Surfaces for Rough Environments

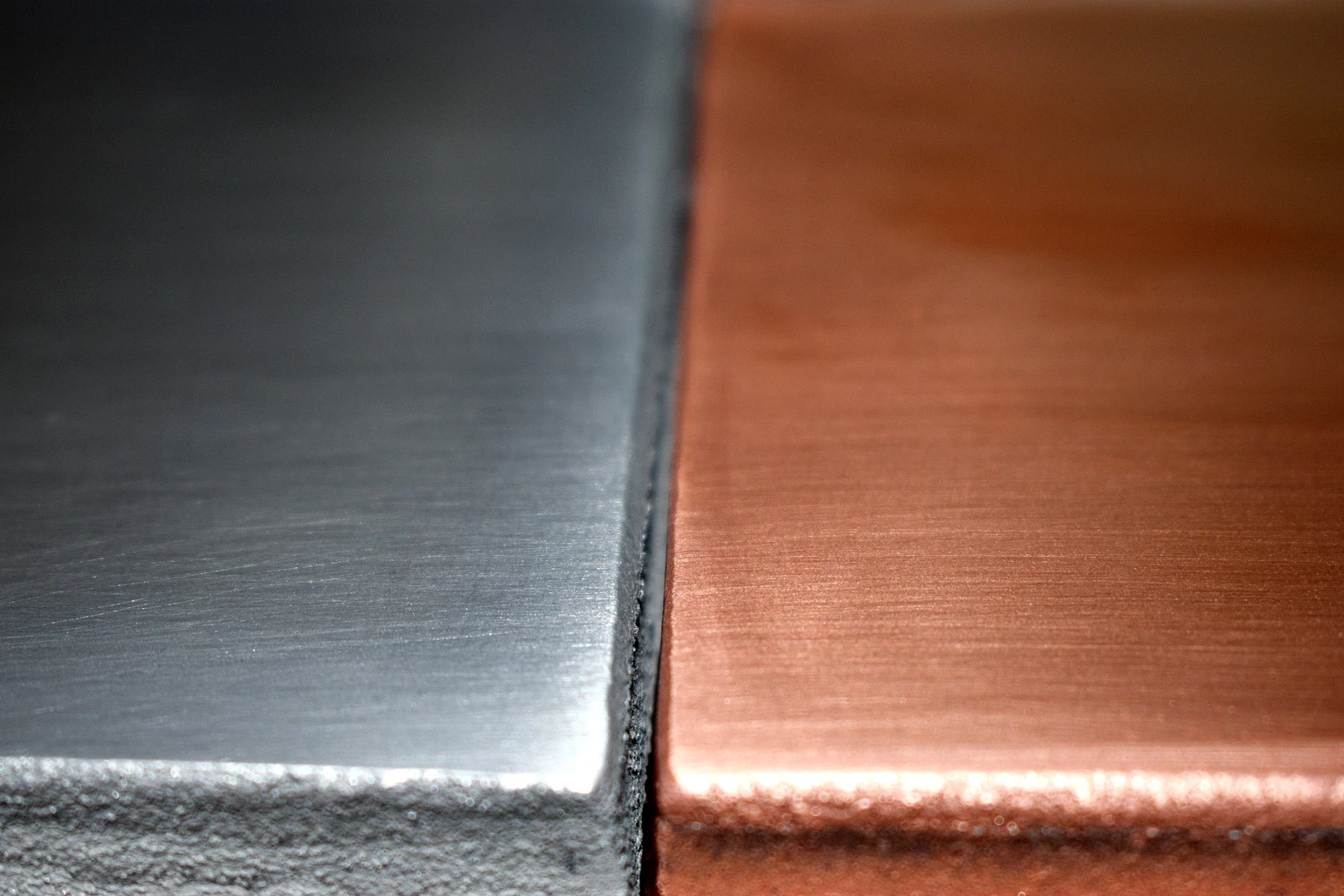

One feature that varies widely among many industries is coating roughness. Smooth coatings are popular for parts with critical dimensions, cosmetic appearance requirements, and vacuum sealing applications but rough coatings have a niche of their own.

Rough coatings deposited on a metal surface have excellent bond strength properties up to 7000 PSI and can be used to increase the lifespan of equipment used in high wear applications like Brake Pads, Boilers, robotic pick-and-place and other industrial applications. These same rough coatings deposited onto chamber assemblies and shields to capture, recycle and refurbish the equipment used in CVD, PVD and other thin film deposition processes. Rough coatings can also be deposited on certain plastics and used for various grip applications.

Although these rough Twin Wire Arc Sprayed coatings are created using the same general process as others, the parameters of the process are manipulated to create less uniform patterns of single impacted particles. Many overlapping “splats” solidify and create a layer of coating, the key to a rough coating is to adjust parameters to create peaks, valleys and spaces for a rough coating profile. These coatings are often thicker than smooth coatings, ranging between 250 – 800 microns. Rough coatings can be controlled to meet the end user specifications within a range of 50 microinch Ra. Our rough coatings have been measured up to approximately 4000 Microinch Ra.