Galvanizing

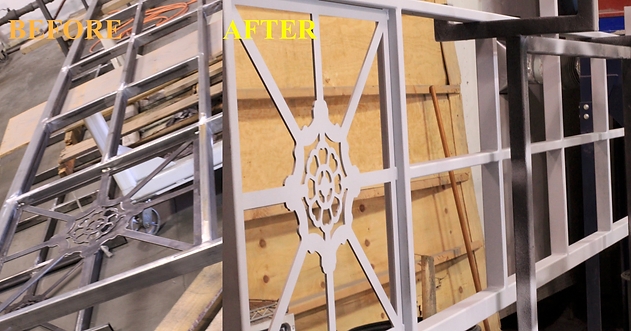

Arc Spray Galvinizing with Zinc, Aluminum or a blend of the two keeps Steel from corroding for long-term protection. It will save money on replacing expensive Steel beams, fencing, ornamental iron, gates, bridges and much more. The Arc Sprayed Galvinizing may be sealed with paint for extra protection. A galvanizing coat of 0.004”-0.006” thickness plus a paint top-coat can provide a minimum of an extra 20 years life to structures.

Galvanizing through Arc Spray can be compared to hot dip galvanizing but has advantages. Firstly, hot dip doesn’t usually offer the Zinc Aluminum Alloy (85/15), Vivid Galvanizing through Arc spray can provide a wide range of pure wires and alloys for different environment. Arc Spray Galvinizing also offers a much lower temperature of processing. This lower temperature (300F) avoids damage to welds and metal distortion that can occur from hot dip galvanizing (800F+). Galvanizing with Thermal Spray is also quicker than paint, spraying semi-molten materials allows the coating to dry the instant it touches the Steel/Iron/Aluminum Substrate. The bead blast prep will also remove any existing corrosion found on parts without Galvinzing.

Galvanizing with Zinc Wire

Zinc has the best Galvanic properties of any galvanizing metal. Zinc is a greater galvanizing metal that is easier to apply than Aluminum. It provides protection to rebar in concrete, refurbishes boats and bridges. Vivid is a galvanizing service provider mostly for gates, rails, and other commercial and residential structures.

Galvanizing with Aluminum Wire

Aluminum is anodic to steel and protects galvanically. Galvanizing with Aluminum Arc Spray may oxidize to become Aluminum Oxide over time but the Al2O3 is less reactive than metal and will prevent rust issues.

85/15 Zinc Aluminum Wire

Aluminum acts as an oxidizing protectant while Zinc important as a sacrificial metal. This material can be machined for a better finish.