Industrial Coating Services

At Vivid Inc., we provide superior-quality thermal spray and liquid coating solutions using high-performance coatings for various products and equipment. Numerous industries rely on our services to ensure optimal performance and better protection, providing the fastest turn-around through our extensive manufacturing process.

SERVICES

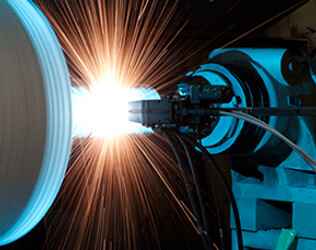

Thermal Spray Services

We have a variety of thermal spray solutions for every application. These are environmentally friendly and an excellent alternative for those who want to cut costs for large production runs. We can keep up with your demands using state-of-the-art technology while delivering consistent results each time.

Our range of thermal spray applications:

- Plasma spray coating: The most popular form of thermal spray application is plasma spray coating. It’s versatile and primarily used in demanding industries due to its wide array of coating materials including ceramic coats. A semi-molten powder coat material is sprayed onto a surface for coating.

- Twin arc spray: We specialize in twin arc spray coating, where a thermal metal coating spray material is deposited on parts susceptible to corrosion and erosion. We use automated spray equipment to produce this layer of protection, increasing a product’s lifespan while protecting its components.

- Cold spray: Also known as supersonic particle deposition, this high-energy metal coating spray solution uses a heated high-pressure carrier gas to deposit or accelerate metal powders through a supersonic nozzle to facilitate particle adhesion.

- Flame spray: Using a heat source to melt powder or wire form into a sprayable coating, flame spray can metalize a substrate for superior protection on surfaces against innumerable environmental conditions while reducing the need for constant maintenance.

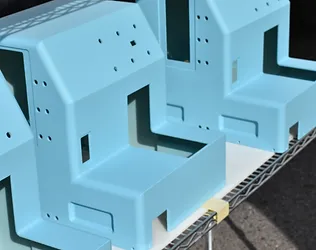

High-Performance Coatings

For high-performance requirements, our high-performance conductive and class A coatings and paints are used for high levels of protection and performance. These are primarily utilized for EMI shielding, protection against abrasion issues, cosmetic appearance, and diverse thermal conductivity applications.

Our different high-performance coating services:

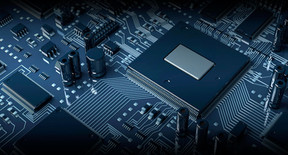

- EMI/RFI shielding: Our expansive range of conductive coatings is predominantly used to shield electronics against EMI/RFI and can also prevent electrostatic discharge. These paints and thermal coatings are applied on the plastic substrate using air atomizing equipment or thermal coating systems.

- Class A Paint: We paint plastics and metal substrates of various chemical make-ups. It includes preparatory services to ensure the substrate for perfect adhesion. Clients can choose from water-based, powder, and polyurethane paints.

- Thick film technology: An additive process that utilizes conductors, resistors, and dielectric pastes; this process is used to produce electronic modules or devices. The pastes contain a mixture of glass and metal oxides and are screen-printed or fired to form the circuit.

Galvanization

Using the arc spray process, galvanizing involves applying a protective Zinc, Aluminum, or a blend of the two to iron or steel for long-term protection. It’s ideally used in applications where these metals are constantly exposed to destructive environmental factors.

Applications of galvanization:

- Sheet metals

- Steel beams

- Iron fencing

- Machine parts

- Metal pipes and wires

ABOUT

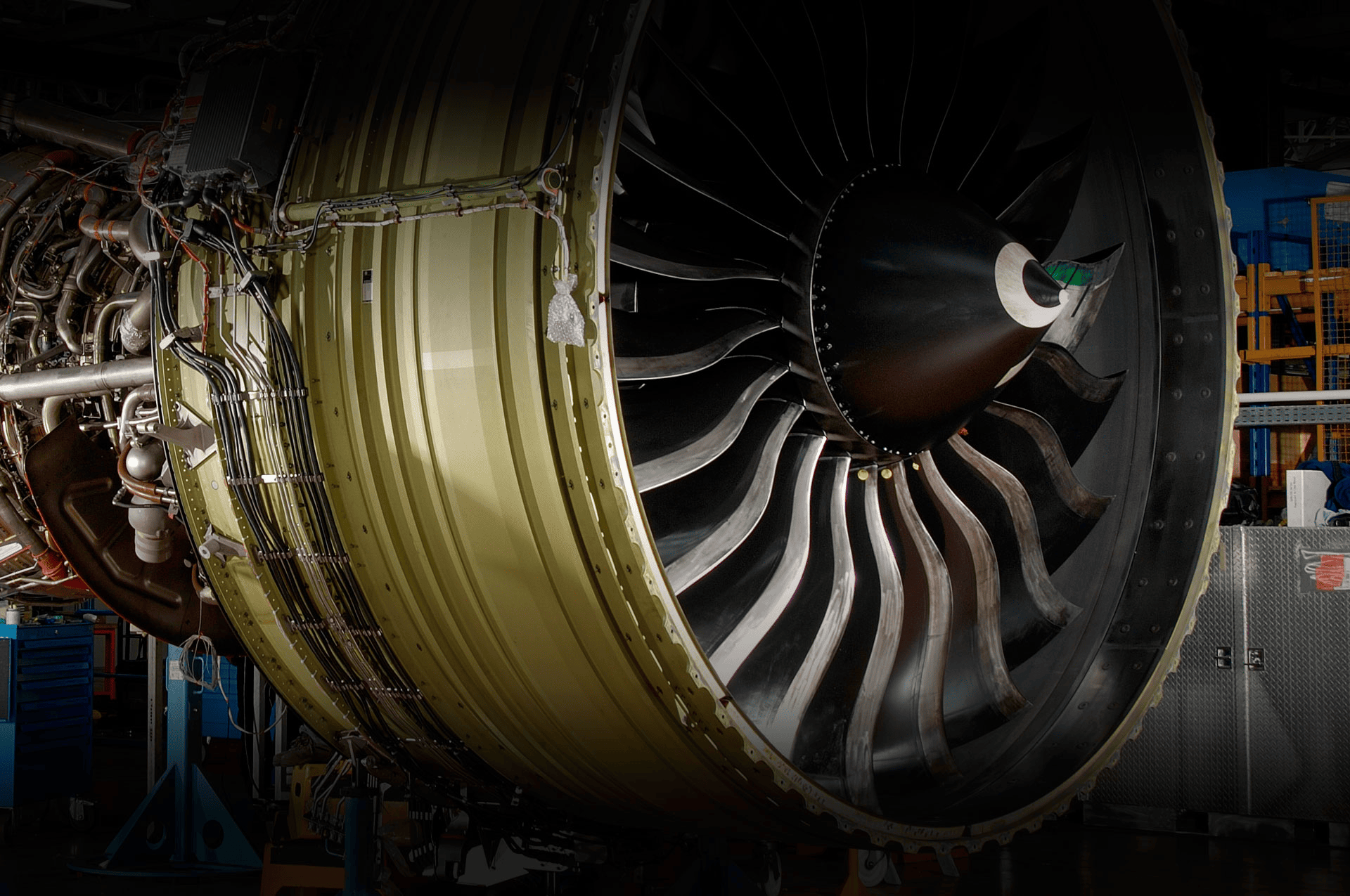

Vivid Inc. was formed in 1990 as three managers from Spectra-Physics branched the paint coatings division into an independent entity. Funded with over one million in environmentally safe painting equipment, Vivid began providing wet paint coatings to meet environmental quality requirements of both state and federal regulation. Since then our customers needs have grown and so have our services. We now offer multiple Thermal Spray technology including Plamsa, Twin Wire Arc, and Cold Spray.

Vivid is ISO 9001:2015 certified and we are committed to providing the highest quality to meet and surpass our customers expectations.

Today, Vivid has grown to be one of the largest materials coating providers in the Silicon Valley. Our customers include a number of the world’s leading equipment manufacturer’s in such industries as semiconductor, telecommunications, automotive and medical. We continue to fuel this growth through our commitment to keeping abreast with the latest technologies and continually improving our automation processes. Vivid also prides itself in complying with complex regulations both in the US and around the world.

CLIENTS

CONTACT

Inquiries

"*" indicates required fields

Head Office

Campbell, CA 95008Email: info@vividinc.com

Office: 408-982-9101

Fax: 408-987-0107

Employment

To apply for a job with Vivid Inc., please send a cover letter together with your Resume to: info@vividinc.com

Get a quote: 408-502-6966

We aim to support our clients by eliminating inefficiencies in their final product. Our range of thermal spray applications and coatings will ensure success in all your projects. If you’re interested and want to know more, don’t hesitate to contact us today. Request a quote, and our team will develop a solution tailored to your needs.