Thermal Spray Coating Services to Protect the Product for Optimal Performance

Vivid Inc. is a leader in thermal spray technologies. We provide a vast array of methods to meet your coating needs without compromising quality.

We have an in-house facility where we perform all of our thermal spray techniques, utilizing state-of-the-art equipment to ensure consistency.

We specialize in several thermal spray coatings, for example thermal sprayed zinc and aluminum metals. It’s used in various industries for a multitude of applications. Multiple options mean we can choose the best application compatible with your product and its requirements. Our experts are well-versed in all aspects of thermal spray coating, from preparation to application.

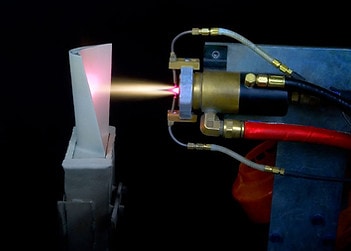

Thermal Spray Coating Methods

We have different high-end metal spray coating methods to improve its efficiency. These are designed to protect the product for optimal performance while enhancing its durability against different factors, such as corrosion, oxidation, weather, and erosion. It also strengthens and fixes worn or damaged surfaces.

Our wide range of thermal spray coating options includes the following:

Plasma Spray

Applications:

Turbine combustion chambers

Seal ring grooves in aero-engine turbines

Diesel engine piston rings

Manufacturing equipment refurbishment

High corrosive dielectric applications

PVD/CVD chambers

Twin Wire Arc

Applications:

Automobile and engine parts

Industrial Mixing Equipment

Galvanizing industrial steel

Marine equipment

Wind turbine components

EMI/RFI shielding plastic enclosures

CVD/PVD chambers

Cold Spray

Applications:

Busbars

Hybrid-heatsink

Brake discs

Sputtering target

Why Opt for Thermal Spraying?

Increasing the corrosion-resistant levels of a part or component is essential in any industry. This thermal spray method will protect these materials from environmental and man-made factors. Thermal spray coating is a practical choice as it offers a solid bonding to the substrate and can stand up against extreme temperatures.

It’s better than a cold galvanizing spray because it’s a more comprehensive solution. It doesn’t just protect the surface but also offers outstanding high-temperature performance. The result will ensure that the adhesion is more secure with better galvanic protection.

Choose Us to Fulfill All Your Thermal Spraying Needs

Vivid Inc. has been providing thermal spraying services for many years. It allowed us to hone our crafts using our expertise and the best equipment. So we offer a wide array of options that will adhere to the industrial standards.

With stringent quality control, you’ll experience superior outcomes. If you want to learn more about our services, feel free to contact us today. We’re happy to find a solution to ensure your project’s success. For bigger orders, request a quote, and we’ll give you a competitive price that won’t break the bank.