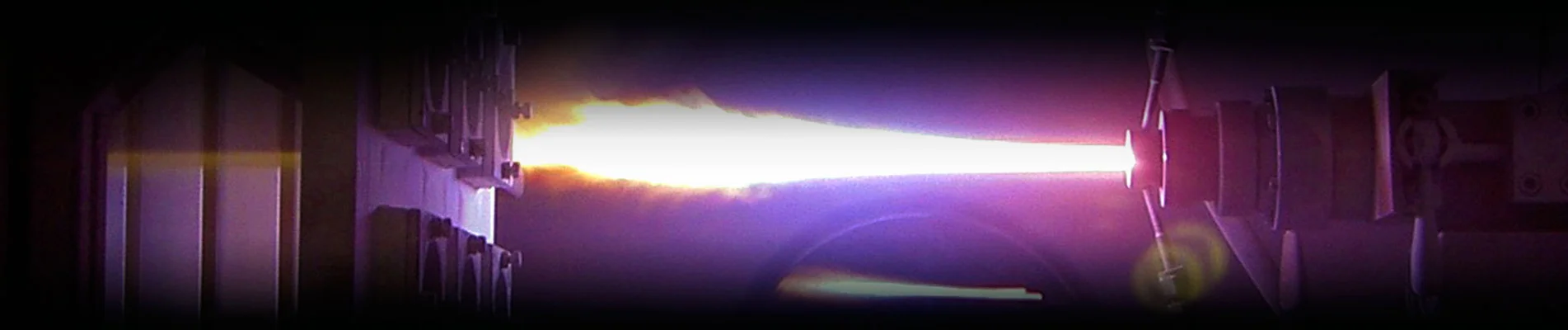

Plasma Spray Process

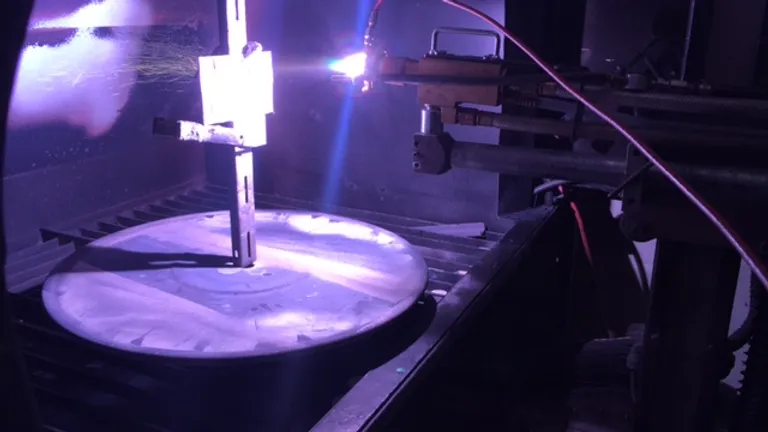

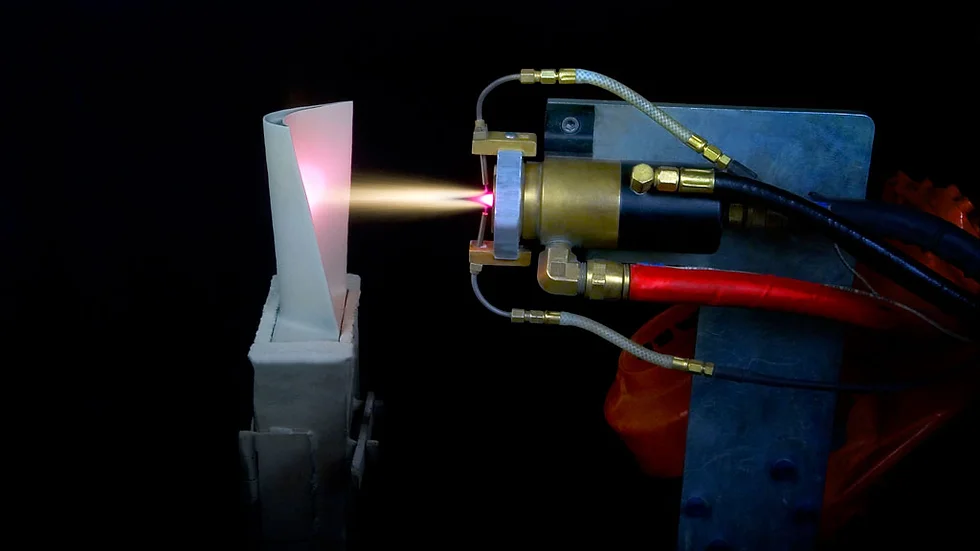

Plasma Spray Process involves spraying semi-molten material onto a substrate surface to provide a functional coating. Material in powder form is injected into a very high temperature plasma spray flame, where it is rapidly heated and accelerated to a high velocity. The hot material impacts on the substrate surface and rapidly cools to form the coating. This process is sometimes referred to as a cold process(relative to the substrate material) since the plasma sprayed substrate temperature can be kept low during processing thus avoiding damage. The Plasma Spray Process can help avoid unwanted metallurgical changes and distortion to the substrate material.

The plasma spray gun is comprised of a anode and cathode, both of which are water-cooled. The plasma spray requires gas, typically argon, nitrogen, hydrogen, or helium. This gas flows around the cathode and through the anode, which is a constricted nozzle. The plasma spray is initiated by a high voltage discharge that causes localized ionization and a conductive path for a DC arc to form between the cathode and anode. The resistance heating from the arc causes the gas to reach extreme temperatures, dissociate and ionize to form plasma. The plasma spray exits the anode nozzle as a free or neutral plasma flame or plasma which does not carry electric current. This is different than the Plasma Transferred Arc coating process, in which the arc extends to the surface to be coated. When the plasma is stabilized and ready for spraying, the electric arc extends down the nozzle, instead of shorting out to the nearest edge of the anode nozzle. This stretching of the arc is due to a thermal pinch effect. Cold gas around the surface of the water-cooled anode nozzle being electrically non-conductive constricts the plasma arc, raising its temperature and velocity. Powder is fed into the plasma spray flame most commonly via an external powder port mounted near the anode nozzle exit. The powder is so rapidly heated and accelerated that spray distances can reach as much as 25 to 150mm.

The plasma spray process is most commonly used in normal atmospheric conditions and referred as Atmospheric Plasma Spray (APS). Some plasma spraying is conducted in protective environments using vacuum chambers normally back filled with a protective gas at low pressure. This is referred as Vacuum Plasma Spray (VPS) or Low Pressure Plasma Spray (LPPS).

Advantages and Disadvantages of Plasma

Advantages of Plasma Spray

- Plasma spray is a medium is a lower temperature process compared to HVOF. Plasma Spray technology won’t damage, create metallurgical changes or distort most substrate materials.

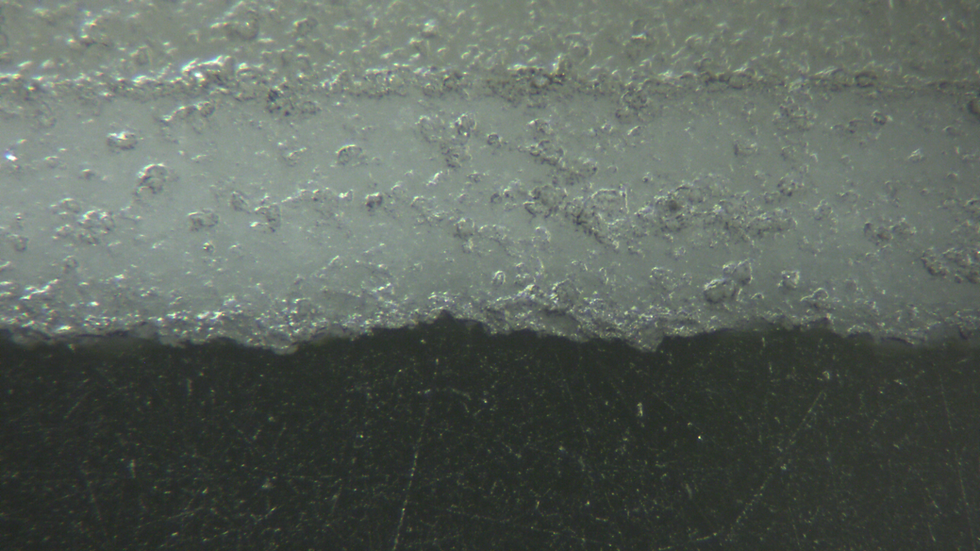

- Plasma spray provides a smoother finish with a low RA.

- The porosity of Plasma Spray can be as low as 1%, a positive attribute regarding any functionality.

- Plasma Spray does not carry electric current.

- Overall significantly stronger, cleaner, and denser than the other thermal spray processes.

- Application of very high melting point materials such as refractory metals like tungsten, and ceramics like zircon unlike combustion processes.

Disadvantages of Plasma

- Potentially higher relative cost and complexity of process compared to Twin Wire Arc Spray

- Plasma Spray temperature is not low enough to be sprayed onto most plastic substrates

Versatile & Effective Plasma Spray Coating Services

We are now the go-to choice for reliable & high-quality coating solutions across The Bay Area. At Vivid Inc., we specialize in plasma spray coating services that enhance the performance and durability of your products.

Vivid Inc. is committed to providing the industry’s best plasma spray coating & many other advanced surfacing technologies. Our team follows ISO standards to enhance the plasma coating process. We inspect every step to ensure the consistent quality.

Don’t Compromise on Quality. Choose Vivid’s Plasma Spray Coating Services Now!

Our Plasma Spray Coating Process

Plasma spray coatings are applied through a high-temperature method, where powdered coating material is introduced into a plasma plume. This material swiftly heats up and is propelled towards the substrate. Upon reaching the surface, it cools down; creating a durable coating that enhances the value of your end product, component, or assembly.

Why Choose Plasma Spray Coating?

1. Superior Protection

Plasma spray coatings protect your parts from wear, tear, corrosion, and extreme temperatures. It extends their lifespan and reduces maintenance needs.

2. Enhanced Performance

Coatings can improve properties like conductivity, heat resistance, and lubricity, optimizing your components’ functionality.

3. Wide Material Options

We offer a variety of metal, ceramic, and composite materials to suit your specific application requirements.

4. Versatility

Plasma spray can coat various shapes and sizes, making it suitable for a broad range of components.

Common Material for Plasma Spray

The high temperatures in plasma spray coating enable the application of ceramics and other materials with high melting points. We at Vivid Inc. utilize various materials for plasma spray coating processes, including:

- Aluminum Oxide

- Chrome Oxide

- Zirconium Oxide

- Tungsten Carbide

- Yttrium Oxide

- And others.

The thickness of coatings is customized to suit the component’s application, taking into account factors such as wear and corrosion. In addition to multilayer coating systems, we implement specialized sealing treatments to enhance coating performance.

Get a Quote Now!

Application Areas of Plasma Coating

Because of its versatile nature, plasma coating is used in multiple industries like:

- Automobile

- Power Station

- Mining Industry

- Cement Industry

- Pump Industry

- Marine Industry

- Textile Industry

- Mechanical Engineering

- Aerospace

- Oil & Gas

- Manufacturing

- Consumer electronics

- Batteries

- Sensors

- And many more.

Vivid – Your Partner in Surface Protection

Vivid Inc. is your one-stop shop for all your plasma spray coating needs. We offer comprehensive services, from material selection and process development to expert application and quality control.

Contact Vivid today to get started with your project requirements and see how our plasma spray coating solutions can benefit your components and your business. We look forward to partnering with you to achieve optimal performance and sustainability.

Let’s Discuss Your Need! Contact Us!