High-Mix-Low-Volume – Dynamic Production

High Mix Low Volume allows for more dynamic production because of the intermittent change. Rather than having a high-volume product line running the same exact-copy process continuously, there are multiple products that call for process-focused principles

High Mix Low Volume can help a company grow its process knowledge base and build on its core capabilities. For example, if the new process involves a value-add service like an additional stamping process; the capital equipment, process flow, employees, and systems all need to adapt. A benefit of High Mix Low Volume is the limited demand for inventory and therefore less strain on company cash flow. Multi-use processing equipment and highly organized floor plans are critical to managing and improving Takt time during High Mix Low volume production cycles. Simplifying and maintaining a predictable process for each operator helps ease the transition and leads to lower changeover times. Although not ideal, High Mix Low Volume may require sharing machines with multiple product lines, though systems will minimize the amount of machine sharing to maximize throughput.

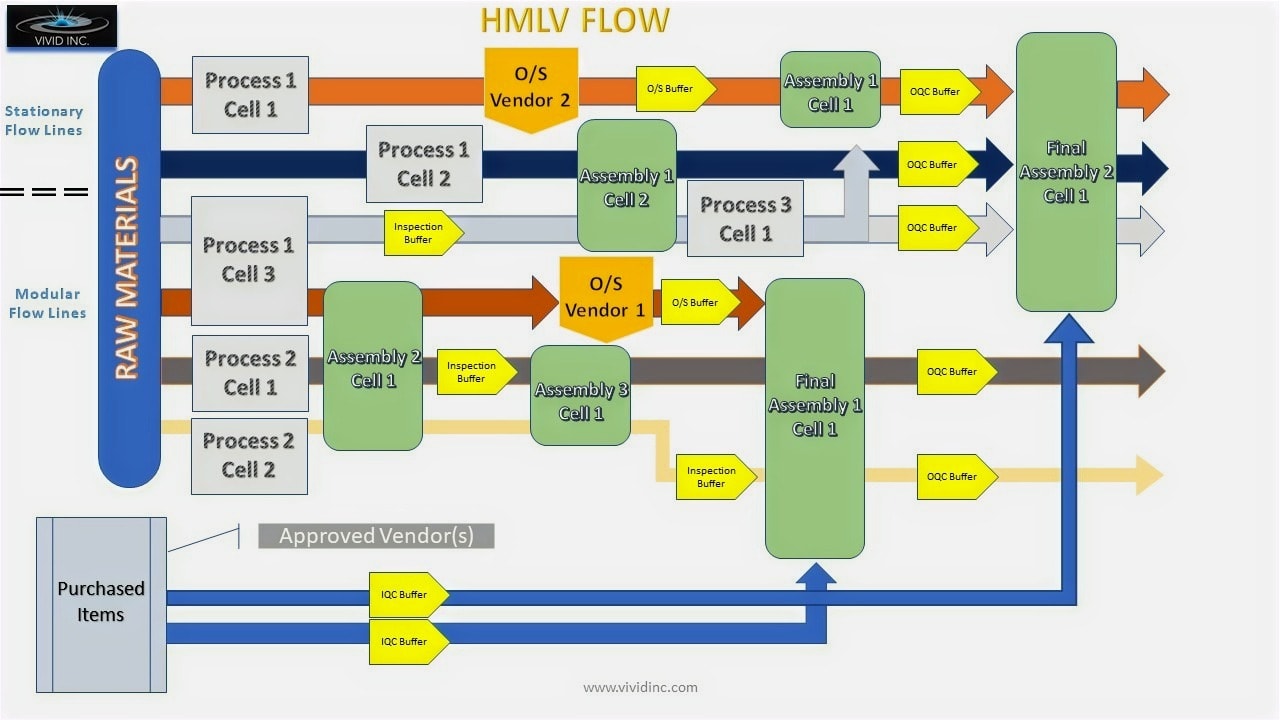

Of course, there are challenges to High Mix Low Volume production that must be met. Most importantly, the employees must be trained and certified in the particular process they are undertaking. High volume production is much easier (and mundane) on operators than High Mix Low Volume. If you put a screw into the same hole on the same part every day, eight hours a day, you would certainly be comfortable with that screw and handy with your screwdriver. High Mix Low Volume is a bit more mentally stimulating, systems must be easily integrated and the transition between systems must be seamless. The production lines are more virtual than physical as the miniature HMLV lines flow simultaneously. Team communication is more important in all directions and 360-degree feedback leads to a more productive integration of new systems. Enterprise Environmental Factors must allow for seamless communication or gating items will be imminent.

Lean principles and Value Stream Mapping may not apply to High Mix Low Volume production. Eliminating minor process waste does not have the same impact on production and overall business value. High Mix Low Volume production is primarily focused on the processes, while traditional lean principles parse values based on individual product lines.

Although many low-mix-high-volume production transitions to large contract manufacturers, there is a volume threshold that varies based on many factors and we are here to help build product until the OEM customer reaches that volume. There is certainly a place for High Mix Low Volume production in the SF Bay Area of California. Vivid is proud to have supported many startups on their journey to become Fortune 500 companies.